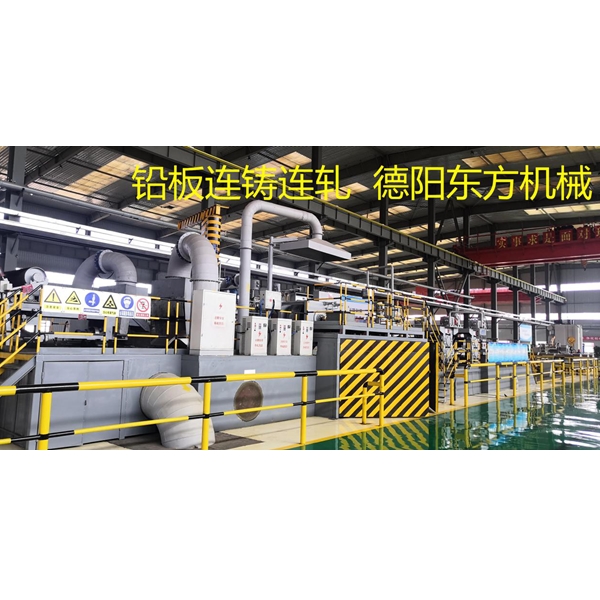

本機組以連續(xù)澆鑄,連續(xù)軋制連續(xù)收卷的工藝方法生產(chǎn)鉛帶。This machine is used to produce lead strip by means of continuous casting, continuous rolling and continuous coiling. 本生產(chǎn)線由熔鉛爐+合金熔煉裝置、保溫爐+過濾箱、五輪式連鑄機、牽引裝置、張力檢測裝置、前剪切機、送料機構(gòu)、連軋機機組及潤滑系統(tǒng)、后剪切機、清洗及干燥裝置,牽引裝置,雙盤自動收卷機、電氣控制系統(tǒng)組成。 This line is composed of leading melting furnace with alloy melting device, holding furnace with filtering box, five-wheel continuous casting machine, haul-off device, tension inspection device, front cutter, feed mechanism, continuous rolling machine and lubrication system, back cutter, cleaning and drying device, haul-off device, automatic dual coiler and electrical control system.

1、 機組用途

本機組以連續(xù)澆鑄,連續(xù)軋制連續(xù)收卷的工藝方法生產(chǎn)鉛帶。

1. Application

This machine is used to produce lead strip by means of continuous casting, continuous rolling and continuous coiling.

2 、機組組成

本生產(chǎn)線由熔鉛爐+合金熔煉裝置、保溫爐+過濾箱、五輪式連鑄機、牽引裝置、張力檢測裝置、前剪切機、送料機構(gòu)、連軋機機組及潤滑系統(tǒng)、后剪切機、清洗及干燥裝置,牽引裝置,雙盤自動收卷機、電氣控制系統(tǒng)組成。

2. Composition

This line is composed of leading melting furnace with alloy melting device, holding furnace with filtering box, five-wheel continuous casting machine, haul-off device, tension inspection device, front cutter, feed mechanism, continuous rolling machine and lubrication system, back cutter, cleaning and drying device, haul-off device, automatic dual coiler and electrical control system.

3、 技術(shù)規(guī)范

3. Technical Specification

鑄坯面積 330X22=7260平方毫米

Cross section of cast blank: 330×22=7260mm2

結(jié)晶輪直徑 ∮1500毫米

Casting wheel dia: Ф1500mm

軋輥名義直徑 第1-2道:350毫米 第3-7道:300毫米

Nominal dia. of roller: Pass No.1~No.2: 350mm, pass No.3~No.7: 300mm

終軋速度 0.3-0.6米/秒

Final rolling speed: 0.3~0.6m/s

成品規(guī)格 寬度(250-600)X厚度(0.7-2)毫米

Finished product dimension: length(250mm~600mm) × thickness (0.7mm~2mm)

生產(chǎn)能力 5-12噸/小時

Production capacity: 5~12t/h

成卷規(guī)格 ∮500X∮1100X360(毫米)

Coiling dimension: Ф500×Ф1100×Ф360

成卷重量 約3000公斤Coiling weight: about 3000KG

設備總功率 130千瓦Total power: 130KW

4、 技術(shù)特點:

4. Technical Features

先進的連鑄連軋工藝方式,生產(chǎn)率高,生產(chǎn)過程穩(wěn)定、易于操作,成品率高。

鉛板強度高,抗腐蝕性強,有效降低產(chǎn)品生產(chǎn)成本。

澆鑄系統(tǒng)與熔鉛爐集中布置,統(tǒng)一收集處理排放,清潔環(huán)保。

澆鑄系統(tǒng)結(jié)構(gòu)優(yōu)化,澆鑄過程自動控制,自動隔離氧化渣,結(jié)晶效果好,晶枝間距優(yōu)良。

軋制壓縮比優(yōu)化設計,保證寬帶及厚板的軋制精度要求,質(zhì)量優(yōu)良。

雙盤收卷自動切換,自動化程度高,勞動強度低。

Advanced continuous casting and rolling technical process, with high production efficiency, stable producing procedure, easy for operation, and high finished product rate.

High strength for the lead strips, high erosion resistance, and effectively reduce the production cost.

The casting system and lead melting furnace are in centralized-arrangement, unified collecting, disposal and discharging, clean and good for environmental protection.

The casting system structure is of optimization design, and the casting procedure is controlled automatically, oxidative slug is separated automatically, good for crystallization, with good dentrite arm spacing.

Rolling reduction ratio is of optimization design, which ensures the rolling precision requirement of strip width and thickness, good strip quality.

Automatic dual coiler shifts automatically, with high automation and low labour intensity.